511

Application industries:

- Ferrous and non-ferrous metallurgy

- Mechanical engineering

Объекты применения:- Working layer of lining in contact with metal workpiece

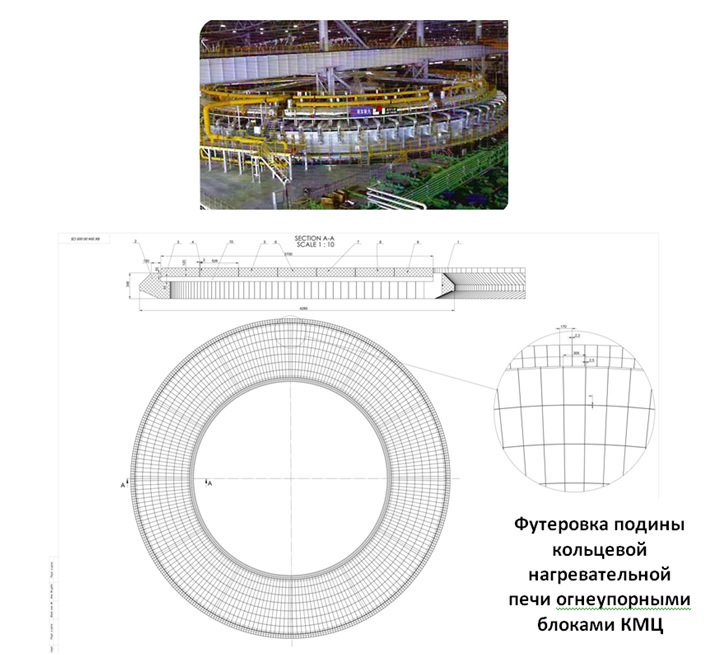

- Furnace bottom

- Furnace roof

- Burner stones

Main advantages:- High temperature resistance

- High corrosion resistance of materials based on fused electrocorundum.

- No interaction with iron scale

- No contamination of metal with non-metallic inclusions in contact with refractory lining

- Constancy of dimensions in service. Products made of coarse-grained fillers have low additional shrinkage (high volume constancy) during their operation under conditions of high temperature exposure

- High resistance to aggressive impact of iron oxide melts of materials containing zirconium dioxide in their composition.

Description:

Improving the wear resistance of the lining and its interaction with scale is one of paramount importance for this process section in metallurgy. The most problematic place in the design of heating furnaces is the bottom. This element of the furnace is subject to intensive destruction due to the impact of several factors: abrasive wear, aggressive impact of iron oxide melts; temperature differences.

In order to solve this problem on the basis of the analysis carried out in Bakor STC developed materials in the system AI2O - ZrO2 - SiO2.

Bakor Scientific and Technical Center offers a set of works for lining of methodical furnace:

- Development, substantiation and issuance of recommendations on rational arrangement of refractories in different zones of the furnace, which ensures uniform and predictable wear of the lining during its operation

- Complete mechanical processing of refractory products

- Bench assembly and marking of individual units and the entire furnace lining

- Author's supervision and installation of the furnace lining by specialists of Bakor STC

- Providing recommendations on furnace commissioning in the technological mode

- Technological support of furnace operation by specialists of the center

- Inspection of furnace lining after completion of its working campaign, analysis of refractory service and issuance of recommendations on furnace refractories for the next campaign.

Options for furnace furnishing:

It is possible to complete with refractory grades of other manufacturers available in the furnace project specification.

Efficiency

Indices of corundum-mullite-zirconium refractories:

|

Al2O3, not less than

|

82,5

|

ZrO2, not less than

|

10,0

|

Softening onset temperature °С, not less than

|

1800

|