511

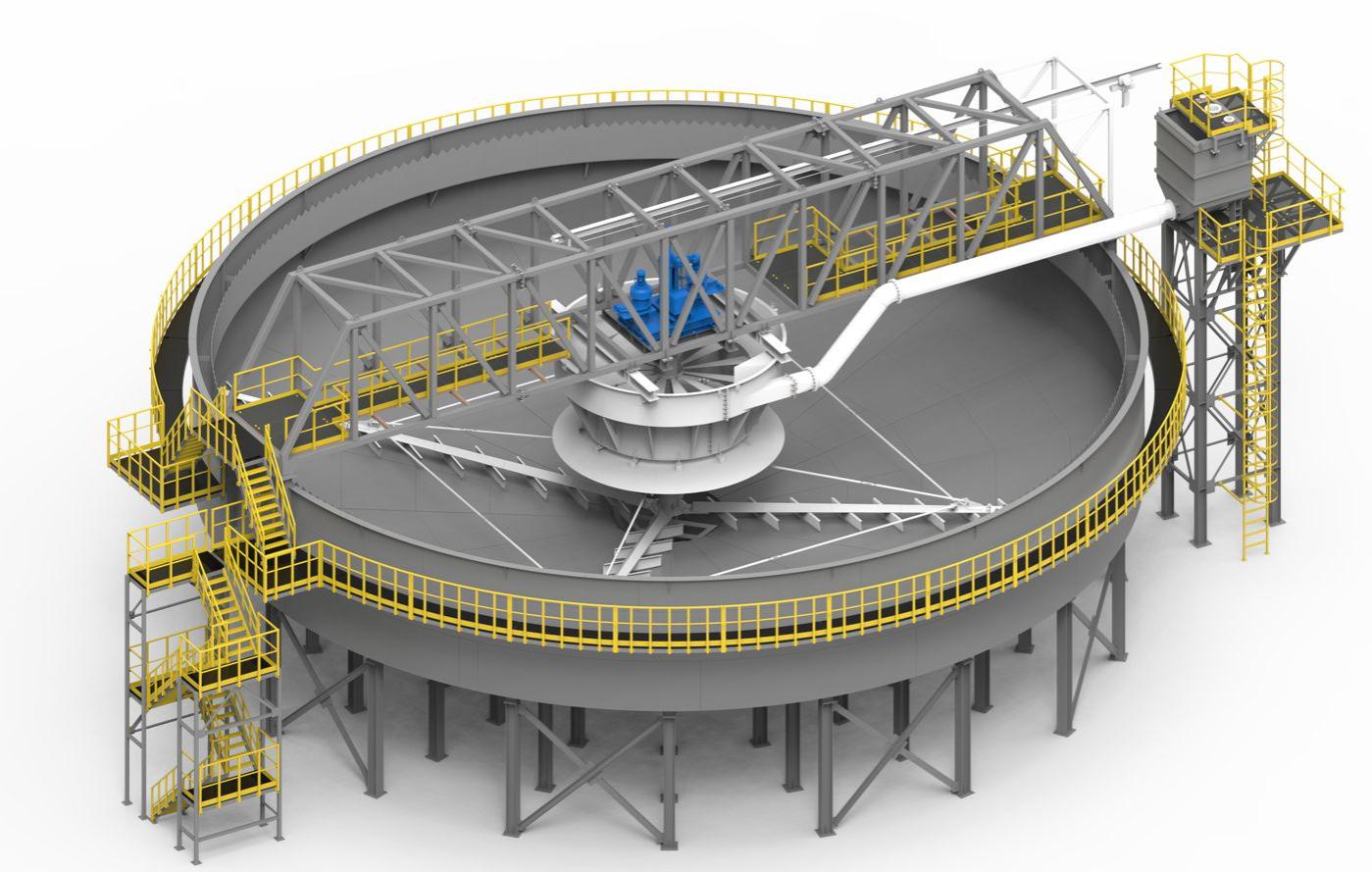

Equipment:

Thickener vat, rake, bridge truss, feed well, reagent preparation and feeding station

Working principle:

Movement is clockwise, with the possibility of counterclockwise movement in emergency situations. Rake lifting, lowering. Feeding of the initial slurry from above through the feed well. Distribution of the pulp to the periphery. Discharge of sands at the bottom of the unit.

Purpose:

Desliming of pulps, clarification and purification of recycled process water, solutions and suspensions at the enterprises of mining and processing, metallurgical, coal, chemical and other industries.

Key advantages:

- The thickening and discharging performance is 30% higher than the thickeners supplied by competitors;

- High efficiency feed well can ensure degassing and energy dissipation of the feed slurry, improve productivity through rational flocculant feeding and rationally utilize the usable vat area;

- The special design of the drive and lifting system can ensure the normal operation of the equipment under overload and high torque;

- We custom design the rake design according to the characteristics of the feed slurry, which in turn improves the thickening efficiency;

- Our thickeners are equipped with a modern automation system, which controls the whole thickening process from flocculants feeding, rake lifting to bottom discharge control;

- Technical specialists of Bakor STC provide warranty support and service maintenance of our equipment.

Labeling:

СЦ – 2,5 (12, 18, 24, 30) т\л

- С - thickener

- Ц – central drive

- 2,5 (12, 18, 24, 30) – diameter

- т – heavy type

- л – light type