Price on request

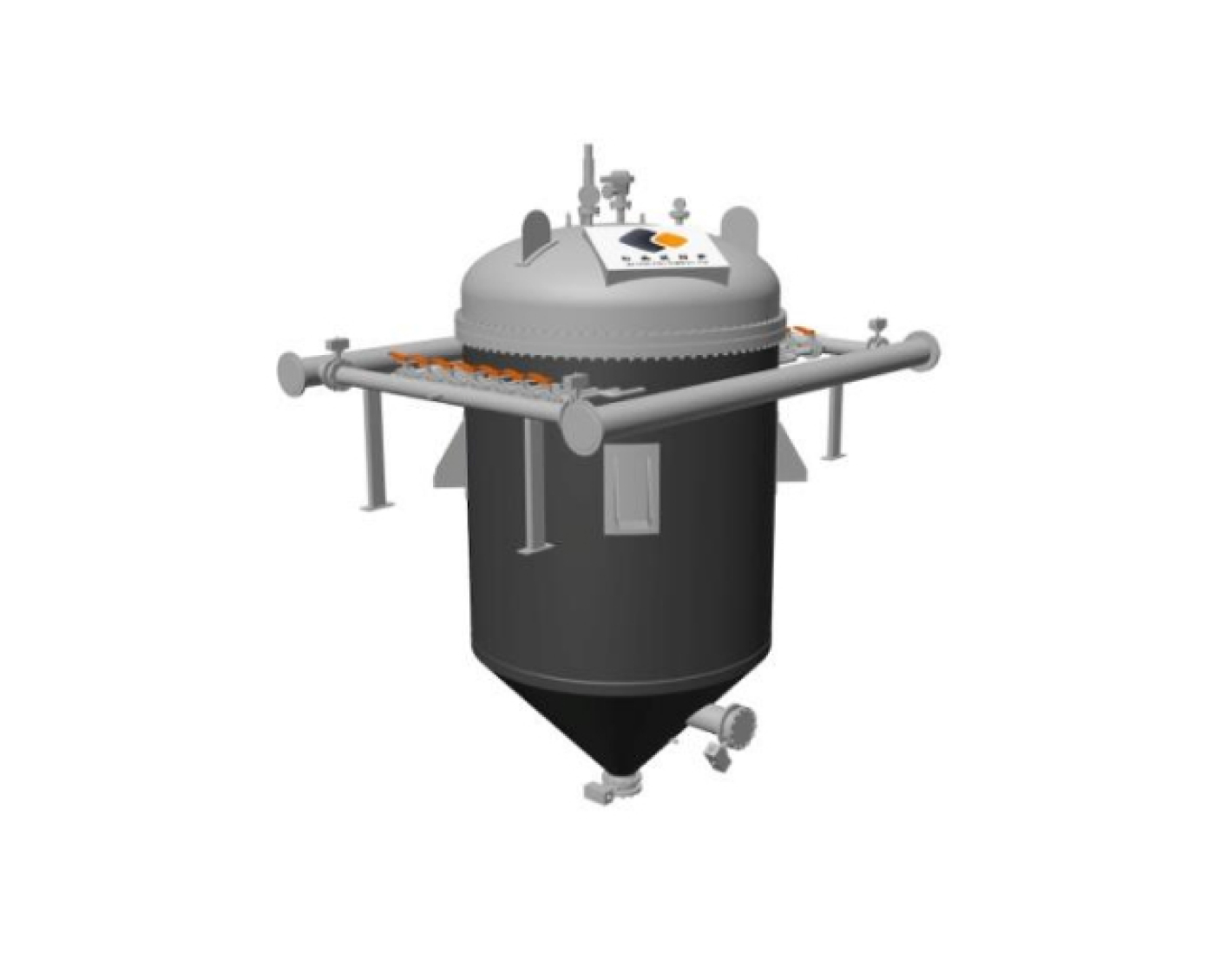

Working principle:

The liquid is purified from insoluble solids by passing through porous permeable ceramic elements. Filtration in the ceramic cartridge filter (CCF) unit is carried out under pressure. The liquid is fed into the CCF unit, pressed through the pores of ceramics into the inner cavity of cartridge elements and through manifolds is discharged from the unit. At the same time, a sludge is formed on the outer surface of the cartridges, which, in turn, acts as an additional filtering layer.

When the sludge reaches a certain thickness, the filtration process stops due to decreased capacity of the CCF unit. The sludge is removed from the surface of the cartridge elements by a reverse flow of compressed air or filtrate. Sludge, slurry and filtrate residues are removed from the housing of the CCF unit by compressed air supply or under hydrostatic pressure.

Bakor's cartridge ceramic filtering elements, based on Nano-disperse binders, provide 100% exclusion of mechanical impurities and the possibility of organization of closed water circulation, extraction of valuable and burial of solid impurities from tailings in dry form, with minimum costs and maximum productivity.

Efficiency:

High performance - 1.9 m3/m2

99.98% recovery of solids from solutions

Solid content in the filtrate does not exceed 0.001 g/liter

Clean filtrate can be used in closed water recycling systems

Return of valuable solid products to production

Elimination of groundwater contamination with heavy metals

Absence of fine insoluble calcium compounds in the filtrate

Possibility of filtration of hot solutions

Long service life of filter elements - 12 months and more

Selection of filter elements for specific requirements of filtered products

Applications:

The filters are used for filtering a wide class of suspensions, and they are also suitable for separating suspensions with small concentrations of solids and suspensions with elevated temperatures, the cooling of which is unacceptable due to the precipitation of crystals from the liquid.

Key advantages (compared to competitors):

Advantage | Bakor Parameter | Typical for fabric-based competitors |

Pore diameter can be tailored to the specific application | 1-100 microns | 10-100 µm |

High strength | Above 32 MPa in compression | One or two parameters that are as good as Bakor ceramics can be selected, but not all at the same . |

High chemical resistance to many substances at the same time | Acid resistance above 97%, alkali-resistance at least 90%, absolute resistance to organic solvents | |

Ability to work at high temperatures | Limited only by the boiling point of the medium | |

Longer service life of elements | Limited only by the boiling point of the medium | 1-2 months |

Possibility to obtain crystal-clear filtrate without additional purification stages | less than 0.02 g/l (over 99.9% retention efficiency over the entire cycle of operation), ability to retain particles with a diameter of less than 1 µm | Particle retention efficiency is typically less than 98% at start-up, with average particle diameter typically at least 10 µm |

The main advantage of filters using ceramic candles as a filter baffle is that they can combine AT THE SAME TIME many characteristics that are very difficult to obtain with cloth filtration, or only some of them have to be selected. These are high strength and chemical and temperature resistance, increased wear resistance and service life. At the same time on ceramics there is a fundamental possibility to obtain a homogeneous filtering surface with minimal pore sizes, which are actually not achievable on woven materials. This makes it possible to obtain crystal-clear filtrate without additional cleaning stages and the use of a soap bed.

Characteristics and size range:

Characteristics | PKF-20 (rus. ПКФ-20) | PKF-40 (rus. ПКФ-40) | PKF-60 (rus. ПКФ-60) | PKF-80 (rus. ПКФ-80) | PKF-100 (rus. ПКФ-100) | |

Total filtering area | m2 | 20 | 40 | 60 | 80 | 100 |

Labeling:

ПКФ-X, Cartridge ceramic filter with filtering area X m2