511

Application industries:

- Mining and processing industry

- Ferrous and non-ferrous metallurgy

- Chemical and petrochemical industry

Working principle:

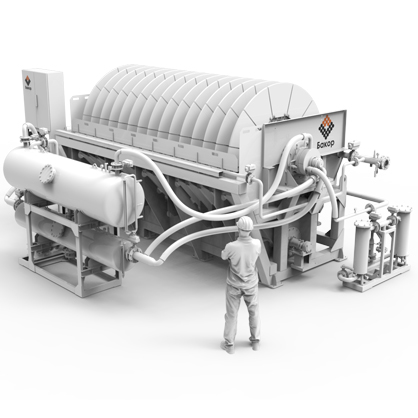

The ceramic disk filter (CDF) is based on ceramic filter elements, which are sector-shaped plates mounted on the filter shaft. As the shaft rotates, the microporous filter elements are immersed in the pulp, where capillary forces cause the formation of cake. The vacuum pump is responsible for the removal of the filtrate from the sector element cavity through discharge lines.

This technology allows to retain maximum solid particles and minimizes air flow, which significantly reduces power consumption for vacuum maintenance.

The dewatered cake is removed from the surface of the CDF filter elements by ceramic knives. After the cake is discharged, the backwash system delivers a small portion of water inside the sector element to activate the filter surface.

The CDF filter features a system of ultrasonic and acid regeneration of filter elements, providing the most effective cleaning.

Options by equipment:- Acid station

- Filtrate station

- Acid regeneration effluent neutralization station

Efficiency/main advantages: - The specific capacity of the CDF filter is 1.5-5 times higher than similar vacuum and press filters

- Average moisture content of CDF concentrates is 8-10 %

- Energy consumption of CDF filter is 6-10 times lower compared to vacuum fabric and press filters.

- Filtration of ceramic disk filter without losses of finely ground concentrates with the content of class - 0,040 mm up to 99%.

- High filtrate purity - solid content in the filtrate 0.001-0.005 g/L

Reduced operating costs - Reduced filter element replacement costs

- No abrasive wear of parts in the filtrate removal system

- Minimal operational maintenance requirements

- High corrosion resistance of filter construction

Continuous operation - Reduced costs for conveyor equipment,

- High operational readiness of the filter - 98%,

- High filter pad capacity

Ecological efficiency - Eliminated aerosol emissions in the filter working area due to the absence of cake blowing operation

- Clean filtrate that does not pollute production and the environment.

Operational efficiency- Significant reduction in operating costs

- Continuous operation and automation

- Compact and simple filter design is characterized by low metal consumption, easy installation and interchangeability of all filter elements.

- 100% blocking of the cake formation zone and dewatering zone from backwash water and filtrate ingress

- Vacuum regulation in the cake formation and dewatering zone

- Backwash pressure control

- Tank and agitator design ensures uniform mixing of high-density concentrates

|

Parameters

| |

CDF-0.5 (rus. КДФ-0.5)

|

CDF-30 (rus. КДФ-30)

|

CDF-90 (rus. КДФ-90)

|

CDF-95 (rus. КДФ-95)

|

CDF-108 (rus. КДФ-108)

|

CDF-140 (rus. КДФ-140)

|

|---|

|

Filtration area

| m2 |

0,5

|

30

|

90

|

95

|

108

|

140

|

|

Number of disks

|

pcs

|

1

|

6

|

15

|

16

|

18

|

14

|

|

Размер фильтра

| |

CDF-0.5 (rus. КДФ-0.5)

|

CDF-30 (rus. КДФ-30)

|

CDF-90 (rus. КДФ-90)

|

CDF-95 (rus. КДФ-95)

|

CDF-108 (rus. КДФ-108)

|

CDF-140 (rus. КДФ-140)

|

|---|

|

Length

|

mm

|

975

|

4850

|

6900

|

7200

|

8100

|

7500

|

|

Width

|

mm

|

995

|

3910

|

3400

|

3400

|

3400

|

4200

|

|

Height

|

mm

|

1280

|

3300

|

3345

|

3345

|

3345

|

4500

|

|

Setting capacity

|

kW

|

5

|

40

|

55

|

55

|

55

|

75

|

|

Filter weight (dry)

|

tons

|

0,21

|

11,5

|

17,5

|

18,8

|

22,0

|

26,5

|

Labeling:|

КДФ-

|

Ceramic disk filter

|

|

"Index"

|

Filtration area

|