Price on request

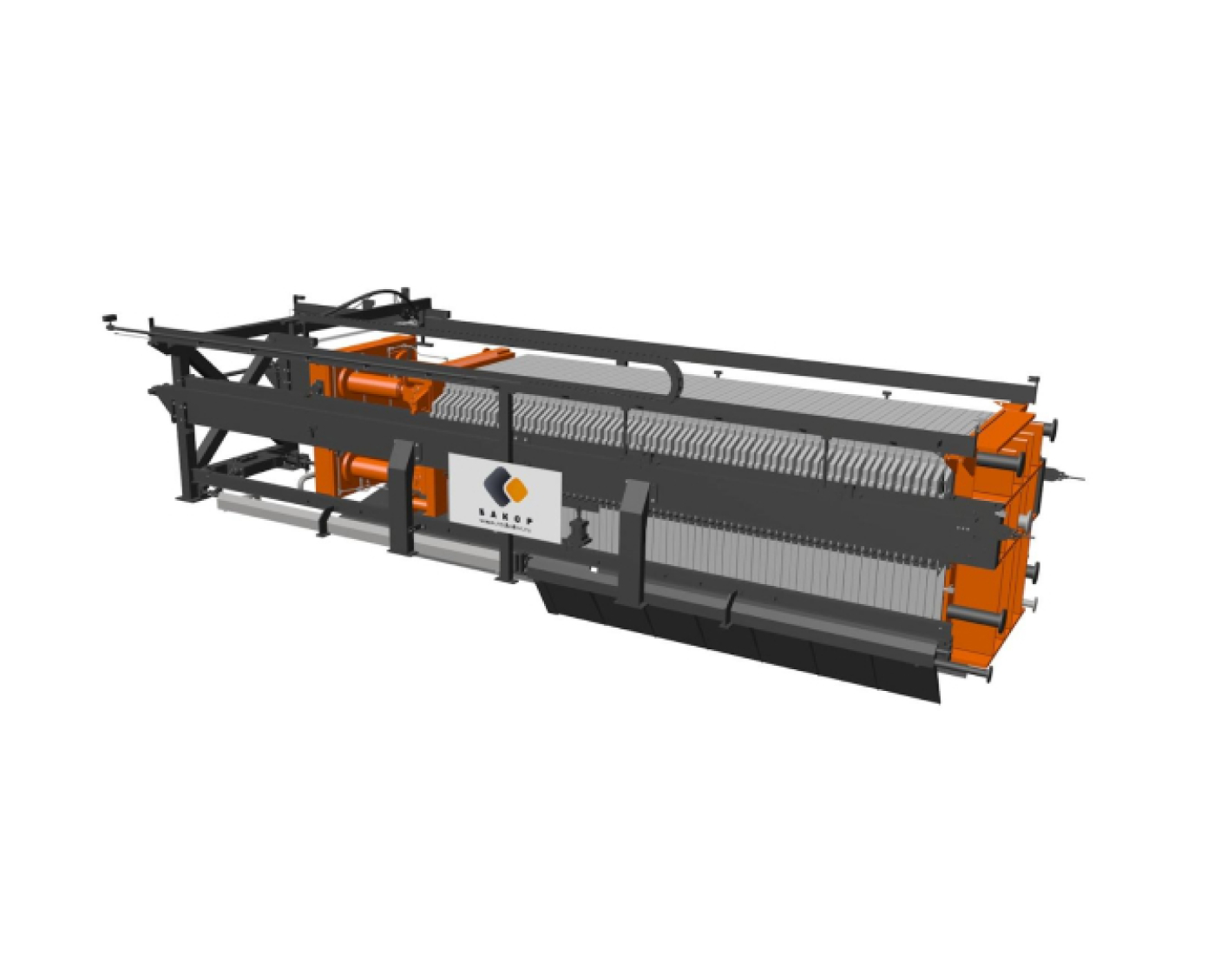

Working principle:

The filter press introduces pulp under high pressure into the cavities (chambers) formed between adjacent vertical plates.

During the filtration cycle, the plates are pressed firmly against each other by means of special hydraulic pushers, sealing them against the internal pressure acting on the pulp side.

The pressure from the pulp side is applied until the filtrate, after passing through the filter cloths, exits in such a quantity that the required degree of dewatering is achieved.

Optional:

Efficiency:

The duration of the main operations on horizontal filter presses depends on the properties of the filtered sludge and the filtering mode.

The residual moisture and purity of the filtrate depends on the correct selection of the filter screen and the filtering conditions

Objects of application:

Non-ferrous metallurgy: dewatering of non-ferrous ore concentrate slurries; fine treatment of electrolyte solutions; dewatering of metallurgical effluents;

Ferrous metallurgy: dewatering of iron ore concentrates; dewatering of neutralized effluents of pickling departments; dewatering of sludge from wet gas cleaning of metallurgical furnaces;

Chemical industry: filtration and thorough washing of sludge in the production of chemicals; fine cleaning of solvents and spinning solutions in the production of artificial fibers (nitron, viscose, PVC, etc.);

Coal industry: filtration of coal suspensions and raw coal slurries;

Sugar industry: filtration of juice of 1st saturation; filtration of condensed juice of 1st saturation during processing of beet and raw sugar;

Manufacture of juices, beverages, winemaking: fine purification of juices, wines and beer; dehydration of yeast sediments of winemaking;

Industrial wastewater treatment: dewatering of thickened sludge from wastewater treatment plants;

Utilities: dewatering of municipal wastewater; dewatering of sludge from water treatment plants.

Models and Characteristics:

Characteristics | Total filtering area, m2 | Number of plates 2*2, pcs. |

|---|---|---|

HPF-400/2000 (rus. ГПФ-400/2000) | 400 | 72 |

HPF-300/2000 (rus. ГПФ-300/2000) | 300 | 54 |

HPF-200/2000 (rus. ГПФ-200/2000) | 200 | 34 |

Characteristics | Total filtering area, m2 | Number of plates 1,5*1,5, pcs. |

|---|---|---|

HPF-200/1500 (rus. ГПФ-200/1500) | 200 | 72 |

HPF-150/1500 (rus. ГПФ-150/1500) | 150 | 54 |

HPF-100/1500 (rus. ГПФ-100/1500) | 100 | 34 |

Characteristics | Total filtering area, m2 | Number of plates 1,2*1,2, pcs. |

|---|---|---|

HPF-100/1200 (rus. ГПФ-100/1200) | 100 | 54 |

HPF-60/1200 (rus. ГПФ-60/1200) | 60 | 34 |

HPF-40/1200 (rus. ГПФ-40/1200) | 40 | 22 |

Specification and labeling:

ГПФ-400, Horizontal press filter with a filtering area of 400 m2

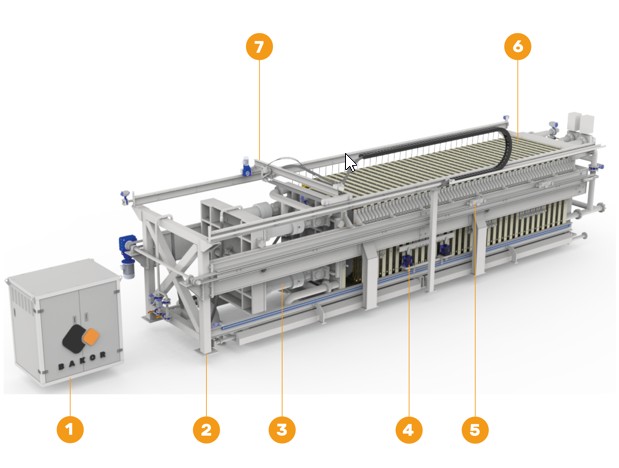

Components:

Oil station

Filtration frame

Support movable plate

Plate shaking unit

Plate moving unit

Filter plate

Fabric washing unit

Комплектация:

Фильтр-пресс

Рама фильтр-пресса

Каплесборник

Механизм перемещения плит

Механизм промывки салфеток

Механизм встряхивания плит

Гидравлическая станция

Комплект фильтровальных плит

Комплект фильтровальных салфеток