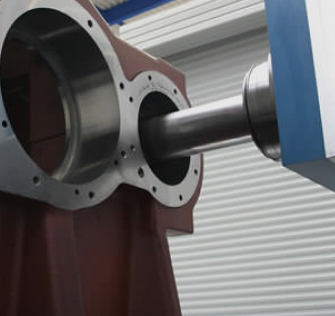

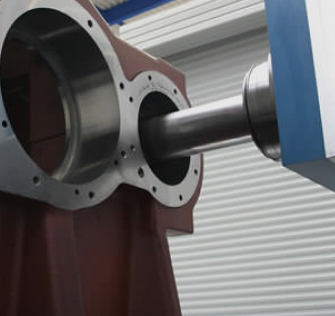

Filtration and separation of liquid and solid media

Filters are used for filtering a wide class of suspensions, and they are also suitable for separating suspensions with a small concentration of solid particles and suspensions with an elevated temperature, cooling of which is unacceptable due to the loss of crystals from the liquid